“Samsung Hits Pause: ASML Chip Gear Delays New US Factory Launch”

Introduction

Samsung has reportedly decided to delay the delivery of advanced chipmaking equipment from ASML for its new semiconductor facility in the United States, according to sources familiar with the matter. This postponement comes amid ongoing challenges in the global semiconductor supply chain and strategic adjustments by major industry players. The equipment, crucial for the production of cutting-edge chips, is part of Samsung’s broader efforts to expand its manufacturing capabilities and maintain its competitive edge in the semiconductor market. The decision to defer these deliveries highlights the complexities and uncertainties facing the tech giant as it navigates geopolitical tensions and evolving market demands.

Impact Of Samsung’s Decision To Postpone ASML Equipment Deliveries On The Semiconductor Industry

Samsung’s recent decision to postpone the delivery of ASML’s chip-making equipment for its new factory in the United States has sent ripples through the semiconductor industry, raising questions about the potential implications for both companies and the broader market. This move, as reported by sources familiar with the matter, underscores the complex dynamics at play in the global semiconductor supply chain, where strategic decisions by major players can have far-reaching consequences.

To begin with, Samsung’s decision to delay the receipt of ASML’s equipment is significant because ASML is a critical supplier of advanced lithography machines, which are essential for producing cutting-edge semiconductors. These machines, particularly the extreme ultraviolet (EUV) lithography systems, are pivotal in enabling manufacturers to produce smaller, more efficient, and more powerful chips. By postponing the delivery, Samsung may be signaling a shift in its production timeline or strategy, which could impact its competitive positioning in the semiconductor market.

Moreover, this postponement could have implications for ASML itself. As a leading supplier of lithography equipment, ASML relies on timely deliveries to maintain its revenue streams and meet its financial targets. A delay in delivery to a major customer like Samsung could affect ASML’s production schedules and financial forecasts. Additionally, it may prompt ASML to reassess its supply chain logistics and customer engagement strategies to mitigate the impact of such delays in the future.

Furthermore, the broader semiconductor industry could also feel the effects of Samsung’s decision. The semiconductor market is characterized by rapid technological advancements and intense competition, with companies striving to outpace each other in innovation and production capacity. Any delay in the deployment of advanced manufacturing equipment could slow down the introduction of new semiconductor products, potentially affecting the supply of chips to various sectors, including consumer electronics, automotive, and telecommunications.

In addition to these immediate impacts, Samsung’s decision may also reflect broader trends and challenges within the semiconductor industry. The industry has been grappling with supply chain disruptions, geopolitical tensions, and fluctuating demand patterns, all of which have contributed to a volatile market environment. By postponing equipment deliveries, Samsung might be attempting to navigate these uncertainties more effectively, perhaps by aligning its production capabilities with anticipated market conditions or by reallocating resources to other strategic initiatives.

Moreover, this development highlights the intricate interdependencies within the semiconductor supply chain. Companies like Samsung and ASML are part of a complex ecosystem where decisions made by one entity can have cascading effects on others. This interconnectedness underscores the importance of collaboration and communication among industry players to ensure resilience and adaptability in the face of challenges.

In conclusion, Samsung’s decision to postpone ASML chip equipment deliveries for its new US factory is a multifaceted issue with potential implications for both companies and the semiconductor industry at large. While the immediate effects may include adjustments to production schedules and financial forecasts, the broader impact could extend to market dynamics and supply chain strategies. As the industry continues to navigate a rapidly changing landscape, the actions of major players like Samsung will undoubtedly play a crucial role in shaping the future of semiconductor manufacturing and innovation.

Reasons Behind Samsung’s Delay In Receiving ASML Chip Equipment For Its US Factory

Samsung’s decision to postpone the delivery of ASML chip equipment for its new factory in the United States has sparked considerable interest and speculation within the semiconductor industry. This delay, as reported by sources familiar with the matter, is not merely a logistical hiccup but rather a strategic maneuver influenced by a confluence of factors. Understanding these reasons requires a closer examination of the current landscape of the semiconductor industry, Samsung’s strategic priorities, and the broader geopolitical context.

To begin with, the semiconductor industry is currently navigating a period of unprecedented demand and supply chain challenges. The global chip shortage, exacerbated by the COVID-19 pandemic, has placed immense pressure on manufacturers to optimize their production capabilities. In this context, Samsung’s decision to delay the receipt of ASML’s advanced lithography equipment could be seen as a tactical move to better align its production timelines with market demand. By postponing the delivery, Samsung may be seeking to synchronize the ramp-up of its new facility with anticipated shifts in market conditions, thereby maximizing operational efficiency and return on investment.

Moreover, Samsung’s strategic priorities play a crucial role in this decision. As a leading player in the semiconductor industry, Samsung is continually evaluating its competitive positioning and long-term growth prospects. The delay in equipment delivery could be part of a broader strategy to recalibrate its production roadmap, ensuring that its new US facility is equipped to produce cutting-edge chips that meet future technological standards. This approach would allow Samsung to maintain its competitive edge in an industry characterized by rapid innovation and technological advancement.

In addition to these industry-specific considerations, the geopolitical landscape also exerts significant influence over Samsung’s operational decisions. The semiconductor sector has become a focal point of geopolitical tensions, particularly between the United States and China. As countries strive to secure their technological sovereignty, companies like Samsung find themselves navigating a complex web of regulatory requirements and trade policies. The delay in equipment delivery could be a response to evolving regulatory landscapes, as Samsung seeks to ensure compliance with US export controls and other relevant policies. By taking a cautious approach, Samsung can mitigate potential risks associated with geopolitical uncertainties and safeguard its long-term interests.

Furthermore, the decision to postpone equipment delivery may also be influenced by Samsung’s internal assessments of its supply chain resilience. The pandemic has underscored the importance of robust supply chain management, prompting companies to reassess their sourcing strategies and contingency plans. By delaying the receipt of ASML equipment, Samsung may be allowing itself additional time to fortify its supply chain, ensuring that it can seamlessly integrate the new equipment into its production processes without disruption.

In conclusion, Samsung’s postponement of ASML chip equipment deliveries for its new US factory is a multifaceted decision shaped by a combination of industry dynamics, strategic priorities, geopolitical considerations, and supply chain assessments. While the delay may initially appear as a setback, it is, in fact, a calculated move that reflects Samsung’s commitment to maintaining its leadership position in the semiconductor industry. As the company continues to navigate this complex landscape, its strategic decisions will undoubtedly have far-reaching implications for the future of semiconductor manufacturing.

How Samsung’s Postponement Of ASML Deliveries Affects Its US Expansion Plans

Samsung’s decision to postpone the delivery of ASML chip-making equipment for its new U.S. factory has raised questions about the potential impact on its expansion plans in the United States. This development comes at a time when the global semiconductor industry is grappling with supply chain disruptions and increasing demand for advanced chips. The delay in equipment delivery could have significant implications for Samsung’s strategic objectives, particularly in its efforts to enhance its manufacturing capabilities and competitiveness in the U.S. market.

ASML, a Dutch company, is the world’s leading supplier of photolithography machines, which are crucial for producing advanced semiconductor chips. These machines are essential for Samsung’s new facility, as they enable the production of cutting-edge chips that power a wide range of electronic devices. By postponing the delivery of this equipment, Samsung may face challenges in meeting its production timelines and fulfilling its commitments to customers and partners.

The decision to delay the delivery of ASML equipment is reportedly linked to Samsung’s reassessment of its construction and operational timelines for the new factory. This reassessment may be influenced by several factors, including the ongoing global semiconductor shortage, logistical challenges, and the need to optimize resource allocation. As Samsung navigates these complexities, the postponement could provide the company with additional time to address potential bottlenecks and ensure that the facility is fully prepared to commence operations once the equipment arrives.

Moreover, the delay in equipment delivery could have broader implications for Samsung’s competitive positioning in the U.S. market. The United States is a critical market for semiconductor manufacturers, given its robust demand for advanced technology and its strategic importance in the global supply chain. By expanding its manufacturing footprint in the U.S., Samsung aims to strengthen its presence and enhance its ability to serve key customers, including major technology companies and automotive manufacturers. However, any delays in the operationalization of the new factory could impact Samsung’s ability to capitalize on these opportunities and maintain its competitive edge.

In addition to affecting Samsung’s expansion plans, the postponement of ASML equipment deliveries may also have ripple effects on the broader semiconductor industry. As one of the leading players in the market, Samsung’s production capabilities and timelines can influence supply dynamics and pricing trends. Any disruptions or delays in Samsung’s manufacturing operations could exacerbate existing supply chain challenges and contribute to further volatility in the semiconductor market.

Despite these potential challenges, Samsung remains committed to its long-term growth strategy and its investment in the U.S. market. The company has emphasized its dedication to enhancing its manufacturing capabilities and supporting the development of advanced technologies. By strategically managing the postponement of equipment deliveries, Samsung aims to mitigate risks and ensure that its new facility is well-positioned to meet future demand.

In conclusion, while the postponement of ASML chip equipment deliveries presents challenges for Samsung’s U.S. expansion plans, it also offers an opportunity for the company to reassess and optimize its strategies. As Samsung navigates this complex landscape, its ability to adapt and respond to evolving market conditions will be crucial in maintaining its leadership position in the semiconductor industry. The coming months will be critical in determining how Samsung’s U.S. expansion unfolds and the extent to which it can leverage its new facility to drive growth and innovation.

The Role Of ASML In Samsung’s Chip Manufacturing Strategy

Samsung’s decision to postpone the delivery of ASML’s chip-making equipment for its new U.S. factory has sparked considerable interest and speculation within the semiconductor industry. ASML, a Dutch company, is renowned for its cutting-edge lithography machines, which are essential for producing advanced semiconductor chips. These machines are pivotal in Samsung’s strategy to maintain its competitive edge in the global chip market. The delay in equipment delivery, therefore, raises questions about the potential impact on Samsung’s manufacturing timelines and strategic objectives.

ASML’s lithography machines, particularly the extreme ultraviolet (EUV) lithography systems, are critical for producing the latest generation of chips. These machines enable the production of smaller, more powerful, and energy-efficient chips, which are in high demand for applications ranging from smartphones to data centers. Samsung, as one of the leading players in the semiconductor industry, relies heavily on ASML’s technology to enhance its manufacturing capabilities and to meet the growing demand for advanced chips. Consequently, any delay in acquiring these machines could have significant implications for Samsung’s production schedules and market competitiveness.

The postponement of ASML equipment deliveries to Samsung’s new U.S. factory may be attributed to several factors. One possible reason is the ongoing global supply chain disruptions, which have affected numerous industries, including semiconductor manufacturing. These disruptions have led to delays in the production and shipment of critical components, potentially impacting the timely delivery of ASML’s machines. Additionally, the complexity and precision required in manufacturing these advanced lithography systems mean that any minor setback in the production process can lead to significant delays.

Moreover, Samsung’s strategic considerations might also play a role in the decision to delay equipment deliveries. The company could be reassessing its production timelines and capacity requirements in light of changing market conditions and demand forecasts. By postponing the delivery of ASML’s equipment, Samsung may be seeking to align its manufacturing capabilities more closely with anticipated market needs, thereby optimizing its production efficiency and resource allocation.

Furthermore, the geopolitical landscape and regulatory environment could also influence Samsung’s decision-making process. The semiconductor industry is increasingly affected by geopolitical tensions and trade policies, particularly between major economies such as the United States and China. Samsung’s new U.S. factory is part of its broader strategy to diversify its manufacturing footprint and mitigate risks associated with geopolitical uncertainties. Delaying equipment deliveries might provide Samsung with additional time to navigate these complexities and ensure compliance with any new regulations or trade agreements.

In conclusion, the postponement of ASML chip equipment deliveries to Samsung’s new U.S. factory underscores the intricate interplay of technological, strategic, and geopolitical factors in the semiconductor industry. While the delay may pose challenges for Samsung’s production timelines, it also reflects the company’s adaptive approach to navigating a rapidly evolving market landscape. As Samsung continues to refine its chip manufacturing strategy, the role of ASML’s advanced lithography technology remains central to its efforts to maintain a leadership position in the global semiconductor market. The industry will undoubtedly be watching closely to see how Samsung addresses these challenges and capitalizes on opportunities in the coming months.

Potential Consequences Of Delayed ASML Equipment On Samsung’s Production Timeline

Samsung’s decision to postpone the delivery of ASML chip-making equipment for its new factory in the United States has sparked considerable discussion within the semiconductor industry. This move, as reported by sources familiar with the matter, could have significant implications for Samsung’s production timeline and its competitive positioning in the global market. The delay in receiving ASML’s advanced lithography machines, which are crucial for manufacturing cutting-edge chips, may affect Samsung’s ability to meet its production targets and fulfill customer demands.

ASML, a Dutch company, is the sole supplier of extreme ultraviolet (EUV) lithography machines, which are essential for producing the most advanced semiconductors. These machines enable the creation of smaller, more powerful, and energy-efficient chips, which are in high demand across various sectors, including consumer electronics, automotive, and telecommunications. Consequently, any delay in acquiring this equipment could hinder Samsung’s efforts to expand its production capabilities and maintain its technological edge over competitors.

The postponement of equipment deliveries could lead to a ripple effect throughout Samsung’s supply chain. For instance, the delay might compel Samsung to adjust its production schedules, potentially leading to a backlog of orders and extended lead times for its customers. This situation could be particularly challenging given the current global semiconductor shortage, which has already strained supply chains and increased pressure on manufacturers to ramp up production.

Moreover, the delay could impact Samsung’s strategic plans to increase its market share in the semiconductor industry. As companies like TSMC and Intel continue to invest heavily in expanding their production capacities, any setback in Samsung’s timeline could result in lost opportunities to capture a larger portion of the market. This is especially critical as the demand for advanced chips is expected to grow exponentially with the proliferation of technologies such as 5G, artificial intelligence, and the Internet of Things.

In addition to potential market share implications, the delay in equipment delivery could also affect Samsung’s financial performance. The semiconductor business is a significant revenue driver for Samsung, and any disruption in production could lead to decreased sales and profitability. Investors and stakeholders may express concerns over the company’s ability to execute its growth strategy effectively, which could, in turn, impact Samsung’s stock performance.

Furthermore, the delay might influence Samsung’s relationships with its customers and partners. Companies relying on Samsung for their chip supplies may seek alternative suppliers to mitigate risks associated with potential production delays. This shift could weaken Samsung’s position as a preferred supplier and erode customer loyalty over time.

In light of these potential consequences, Samsung may need to explore strategies to mitigate the impact of the delayed equipment deliveries. This could involve optimizing existing production lines, investing in alternative technologies, or negotiating with ASML to expedite future deliveries. Additionally, Samsung might consider enhancing its communication with customers and stakeholders to manage expectations and maintain trust during this challenging period.

In conclusion, while the postponement of ASML equipment deliveries for Samsung’s new US factory presents several challenges, it also underscores the importance of strategic planning and adaptability in the rapidly evolving semiconductor industry. As Samsung navigates these complexities, its ability to address the potential consequences effectively will be crucial in maintaining its competitive edge and achieving long-term success.

Analyzing The Strategic Implications Of Samsung’s Equipment Delivery Postponement

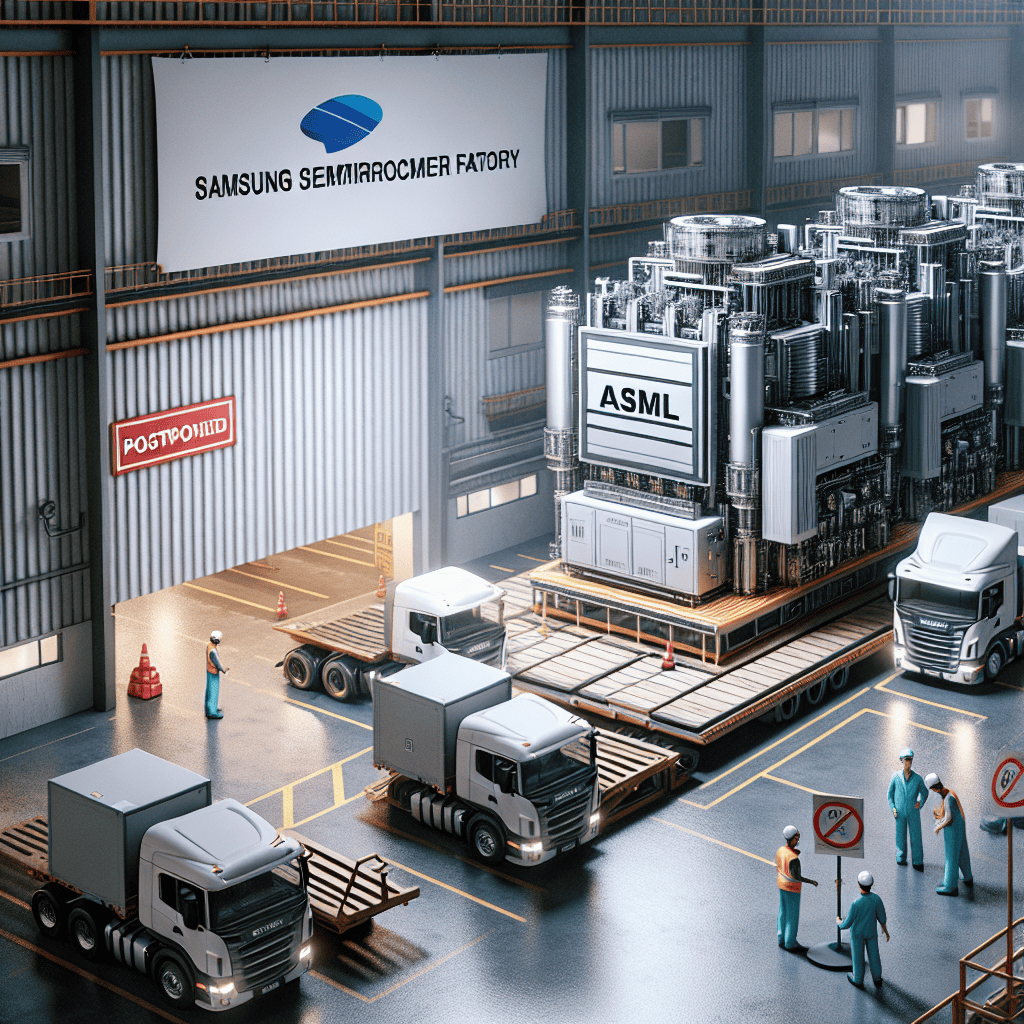

Samsung’s recent decision to postpone the delivery of advanced chip-making equipment from ASML for its new factory in the United States has sparked considerable discussion within the semiconductor industry. This move, while seemingly a logistical adjustment, carries significant strategic implications that merit closer examination. The delay, reportedly due to construction setbacks at the Texas facility, highlights the intricate balance between operational timelines and strategic objectives in the highly competitive semiconductor sector.

To begin with, the postponement underscores the challenges faced by global technology giants in expanding their manufacturing capabilities amid a rapidly evolving geopolitical landscape. Samsung’s decision to build a new factory in the U.S. is part of a broader strategy to diversify its manufacturing footprint and mitigate risks associated with geopolitical tensions, particularly those involving China. By establishing a presence in the U.S., Samsung aims to strengthen its position in the North American market and align itself with the U.S. government’s push for increased domestic semiconductor production. However, the delay in equipment delivery could potentially slow down these strategic efforts, affecting Samsung’s ability to meet growing demand for advanced chips.

Moreover, the postponement may have implications for Samsung’s competitive standing against other semiconductor giants such as Taiwan Semiconductor Manufacturing Company (TSMC) and Intel. Both companies are also investing heavily in expanding their manufacturing capabilities in the U.S., with TSMC building a new facility in Arizona and Intel announcing plans for new plants in Ohio. Any delay in Samsung’s timeline could provide its competitors with a window of opportunity to capture market share, particularly in the lucrative and fast-growing sectors of artificial intelligence, 5G, and automotive chips.

In addition to competitive dynamics, the delay in equipment delivery from ASML, a key supplier of advanced lithography machines, highlights the broader supply chain challenges facing the semiconductor industry. ASML’s extreme ultraviolet (EUV) lithography machines are critical for producing cutting-edge chips, and any disruption in their delivery can have cascading effects on production schedules. This situation underscores the importance of robust supply chain management and the need for semiconductor companies to develop contingency plans to address potential disruptions.

Furthermore, the postponement raises questions about Samsung’s long-term strategic priorities and its ability to adapt to changing market conditions. While the company has demonstrated resilience and adaptability in the past, the current delay may prompt a reevaluation of its investment strategies and timelines. Samsung may need to explore alternative approaches to mitigate the impact of the delay, such as accelerating construction efforts or seeking interim solutions to maintain production momentum.

In conclusion, Samsung’s decision to postpone the delivery of ASML chip-making equipment for its new U.S. factory is a multifaceted issue with significant strategic implications. It highlights the challenges of expanding manufacturing capabilities in a complex geopolitical environment, the competitive pressures within the semiconductor industry, and the critical importance of supply chain resilience. As Samsung navigates these challenges, its ability to adapt and respond effectively will be crucial in maintaining its competitive edge and achieving its long-term strategic objectives. The industry will be closely watching how Samsung addresses these issues and the potential ripple effects on the global semiconductor landscape.

Industry Reactions To Samsung’s Decision To Delay ASML Equipment For US Operations

Samsung’s recent decision to postpone the delivery of ASML chip-making equipment for its new factory in the United States has sparked a wave of reactions across the semiconductor industry. This move, which comes amid a global push to expand chip production capabilities, has been met with a mix of understanding and concern from various stakeholders. Industry experts are closely monitoring the situation, as it could have significant implications for the broader semiconductor supply chain.

To begin with, Samsung’s decision is largely seen as a strategic maneuver to align its production timelines with market demand and operational readiness. The South Korean tech giant is known for its meticulous planning and execution, and this delay is likely a calculated step to ensure that its new facility in the U.S. operates at optimal efficiency once it becomes operational. By postponing the delivery of ASML’s advanced lithography machines, Samsung may be aiming to synchronize the installation of this critical equipment with the completion of other infrastructural elements of the factory.

However, this decision has not been without its critics. Some industry analysts express concern that the delay could exacerbate existing supply chain challenges. The semiconductor industry is already grappling with a shortage of chips, which has affected various sectors, from automotive to consumer electronics. Any further delays in expanding production capacity could potentially prolong these shortages, impacting global markets. Moreover, ASML, a key supplier of photolithography equipment, plays a crucial role in the semiconductor manufacturing process. Delays in the deployment of their machines could ripple through the supply chain, affecting not only Samsung but also other manufacturers relying on timely equipment deliveries.

On the other hand, some industry insiders view Samsung’s decision as a prudent response to the current economic climate. With fluctuating demand and ongoing geopolitical tensions, companies are increasingly cautious about overextending their resources. By delaying the equipment delivery, Samsung may be positioning itself to better navigate these uncertainties, ensuring that it can ramp up production in a more controlled and sustainable manner. This approach could ultimately benefit the company in the long run, allowing it to adapt more flexibly to market changes.

Furthermore, the delay has prompted discussions about the broader implications for the U.S. semiconductor landscape. Samsung’s new factory is part of a larger effort to bolster domestic chip production, a priority for the U.S. government as it seeks to reduce reliance on foreign suppliers. While the postponement may temporarily slow progress, it also highlights the complexities involved in establishing a robust semiconductor manufacturing ecosystem. Industry stakeholders are hopeful that once operational, the factory will contribute significantly to enhancing the U.S.’s chip-making capabilities.

In conclusion, Samsung’s decision to delay ASML equipment deliveries for its new U.S. factory has elicited a range of reactions from industry participants. While some express concern over potential supply chain disruptions, others view it as a strategic move in response to current market conditions. As the situation unfolds, it will be crucial for industry players to remain agile and responsive to the evolving landscape. Ultimately, Samsung’s actions underscore the intricate balance between expanding production capacity and managing operational risks, a challenge that continues to shape the semiconductor industry’s future.

Q&A

1. **What is the main reason for Samsung postponing ASML chip equipment deliveries?**

Samsung is reportedly postponing ASML chip equipment deliveries due to delays in the construction and readiness of its new semiconductor manufacturing facility in the United States.

2. **Which company is affected by the postponement of equipment deliveries?**

ASML, a Dutch company that supplies advanced lithography equipment essential for semiconductor manufacturing, is affected by the postponement.

3. **Where is Samsung’s new factory located?**

Samsung’s new factory is located in the United States, though specific details about the exact location may vary based on the latest reports.

4. **How might this postponement impact Samsung’s production timeline?**

The postponement could potentially delay the start of production at the new facility, affecting Samsung’s timeline for ramping up its semiconductor manufacturing capabilities in the U.S.

5. **What type of equipment does ASML provide to Samsung?**

ASML provides advanced lithography equipment, including extreme ultraviolet (EUV) lithography machines, which are crucial for producing cutting-edge semiconductor chips.

6. **Are there any financial implications mentioned for either Samsung or ASML due to this delay?**

While specific financial implications are not detailed, delays in equipment delivery and factory readiness could impact both companies’ financial projections and operational plans.

7. **What are the broader industry implications of this postponement?**

The postponement could affect the semiconductor supply chain and industry dynamics, potentially influencing timelines for chip production and availability, as well as competitive positioning in the semiconductor market.

Conclusion

Samsung’s decision to postpone the delivery of ASML chip equipment for its new U.S. factory highlights the complexities and challenges in the semiconductor supply chain and manufacturing expansion. This delay could impact Samsung’s timeline for increasing its chip production capacity, potentially affecting its competitive position in the global market. The postponement may also reflect broader industry issues, such as logistical constraints, geopolitical tensions, or strategic realignments in response to evolving market demands. As Samsung navigates these challenges, the situation underscores the critical importance of supply chain agility and strategic planning in the semiconductor industry.