“Golden Dreams, Costly Realities: Navigating the Bullion Boom”

Introduction

Gold miners are facing significant challenges as they navigate rising operational costs despite a booming bullion market. While gold prices have surged, driven by economic uncertainties and increased investor demand, mining companies are grappling with escalating expenses related to labor, energy, and equipment. These cost pressures are squeezing profit margins and complicating efforts to capitalize on the favorable market conditions. As miners strive to balance production efficiency with financial sustainability, the industry is witnessing a complex interplay between market opportunities and operational hurdles. This dynamic landscape underscores the need for strategic adaptation and innovation to ensure long-term viability in the face of fluctuating economic factors.

Rising Operational Costs in the Gold Mining Industry

The gold mining industry, long considered a cornerstone of global economic stability, is currently navigating a paradoxical situation. While the price of gold has experienced a significant surge, reaching levels that have not been seen in years, gold miners are grappling with rising operational costs that threaten to erode their profit margins. This juxtaposition of high market prices and escalating expenses presents a complex challenge for the industry, requiring strategic adjustments and innovative solutions.

To begin with, the increase in gold prices can be attributed to a variety of factors, including geopolitical tensions, inflationary pressures, and a general sense of economic uncertainty that drives investors towards safe-haven assets like gold. This bullish trend in the bullion market has, in theory, created an opportune environment for gold miners to capitalize on higher revenues. However, the reality on the ground is far more nuanced. As gold prices climb, so too do the costs associated with extracting and processing this precious metal.

One of the primary contributors to rising operational costs is the increase in energy prices. Mining operations are energy-intensive, relying heavily on fuel and electricity to power machinery and equipment. With global energy prices on an upward trajectory, miners are facing higher expenses that directly impact their bottom line. Additionally, labor costs have also seen an upward trend. The demand for skilled labor in the mining sector has intensified, leading to increased wages and benefits as companies compete to attract and retain qualified personnel.

Moreover, regulatory and environmental compliance costs have added another layer of financial burden. Governments worldwide are implementing stricter regulations to ensure sustainable mining practices, which, while necessary for environmental protection, require significant investment in new technologies and processes. These compliance measures often necessitate additional capital expenditure, further straining the financial resources of mining companies.

In response to these challenges, gold miners are exploring various strategies to mitigate the impact of rising costs. Technological innovation is at the forefront of these efforts, with companies investing in automation and digitalization to enhance operational efficiency. By leveraging advanced technologies, miners aim to reduce labor costs and improve productivity, thereby offsetting some of the financial pressures they face. Additionally, companies are increasingly focusing on optimizing their supply chains and renegotiating contracts with suppliers to secure more favorable terms.

Furthermore, some miners are diversifying their portfolios to include other minerals and metals, thereby reducing their reliance on gold alone. This diversification strategy not only provides a buffer against volatile gold prices but also opens up new revenue streams that can help offset rising costs. However, such strategic shifts require careful planning and execution to ensure they align with the company’s long-term objectives.

In conclusion, while the current bullion boom presents a lucrative opportunity for gold miners, the simultaneous rise in operational costs poses a significant challenge. Navigating this complex landscape requires a multifaceted approach that combines technological innovation, strategic diversification, and efficient resource management. As the industry continues to evolve, gold miners must remain agile and adaptive, balancing the allure of high gold prices with the realities of escalating expenses. Only by doing so can they sustain profitability and continue to play a vital role in the global economy.

Impact of Inflation on Gold Mining Profit Margins

The gold mining industry, long considered a bastion of stability in the face of economic uncertainty, is currently grappling with a paradoxical challenge. Despite a significant boom in bullion prices, gold miners are finding their profit margins increasingly squeezed due to rising operational costs. This situation is largely attributed to the pervasive impact of inflation, which has permeated various facets of the mining sector, from labor to equipment and energy expenses.

To begin with, the surge in inflation has led to a marked increase in labor costs, a critical component of mining operations. As inflation drives up the cost of living, workers demand higher wages to maintain their purchasing power. Consequently, mining companies are compelled to raise salaries to attract and retain skilled labor, thereby inflating their operational budgets. This escalation in labor expenses is particularly pronounced in regions where mining is a major economic activity, as competition for skilled workers intensifies.

In addition to labor costs, the price of essential mining equipment has also seen a significant uptick. The global supply chain disruptions, exacerbated by the pandemic and geopolitical tensions, have led to shortages and delays in the delivery of mining machinery and parts. As a result, the cost of acquiring and maintaining equipment has risen sharply. This increase not only affects the initial capital expenditure but also inflates ongoing maintenance costs, further eroding profit margins.

Moreover, energy costs have become a formidable challenge for gold miners. The mining process is energy-intensive, requiring substantial amounts of electricity and fuel to extract and process ore. With global energy prices soaring due to a combination of supply constraints and increased demand, mining companies are facing unprecedented energy bills. This situation is compounded by the push towards more sustainable and environmentally friendly practices, which often entail additional costs for implementing cleaner technologies and adhering to stricter regulations.

Despite these challenges, the high price of gold offers a silver lining for miners. The bullion boom, driven by investors seeking safe-haven assets amid economic volatility, has provided a significant revenue boost. However, the benefits of higher gold prices are being partially offset by the rising costs of production. This dynamic has led to a complex financial landscape where miners must carefully balance the potential for increased revenue against the reality of shrinking margins.

In response to these pressures, many gold mining companies are exploring strategies to mitigate the impact of inflation on their operations. Some are investing in automation and digital technologies to enhance efficiency and reduce reliance on labor. Others are seeking to renegotiate supply contracts or diversify their energy sources to manage costs more effectively. Additionally, there is a growing emphasis on strategic mergers and acquisitions, as companies aim to achieve economies of scale and improve their competitive positioning.

In conclusion, while the current bullion boom presents lucrative opportunities for gold miners, the pervasive impact of inflation poses significant challenges to maintaining healthy profit margins. As the industry navigates this complex environment, the ability to adapt and innovate will be crucial in ensuring long-term sustainability and success. The interplay between rising costs and high gold prices underscores the need for strategic foresight and operational agility in the ever-evolving landscape of gold mining.

Strategies for Gold Miners to Manage Escalating Expenses

As the global economy continues to navigate through uncertain waters, the allure of gold as a safe-haven asset has led to a significant boom in bullion prices. This surge has been a boon for investors seeking stability, yet it presents a paradoxical challenge for gold mining companies. While the rising prices of gold should theoretically bolster profits, miners are concurrently grappling with escalating operational costs that threaten to erode their margins. Consequently, gold miners are compelled to devise strategic approaches to manage these burgeoning expenses effectively.

To begin with, one of the primary strategies that gold miners can employ is the optimization of their operational efficiency. By investing in advanced technologies and automation, mining companies can streamline their processes, thereby reducing labor costs and minimizing waste. For instance, the implementation of autonomous vehicles and drones in mining operations can significantly enhance productivity while simultaneously lowering the risk of human error. Moreover, the adoption of data analytics and machine learning can provide valuable insights into operational inefficiencies, enabling miners to make informed decisions that enhance cost-effectiveness.

In addition to technological advancements, gold miners can also focus on strategic partnerships and collaborations. By forming alliances with other companies, miners can share resources and expertise, leading to cost reductions in areas such as exploration, extraction, and transportation. Joint ventures can also facilitate access to new markets and technologies, further enhancing operational efficiency. Furthermore, these partnerships can provide a buffer against market volatility, as shared risks and rewards can lead to more stable financial outcomes.

Another critical approach is the diversification of energy sources. Energy costs constitute a significant portion of mining expenses, and fluctuations in energy prices can have a substantial impact on overall profitability. By investing in renewable energy sources such as solar and wind power, gold miners can mitigate the risks associated with volatile fossil fuel prices. Not only does this strategy offer long-term cost savings, but it also aligns with the growing emphasis on sustainability and environmental responsibility, which can enhance a company’s reputation and appeal to socially conscious investors.

Moreover, gold miners can explore opportunities for vertical integration to gain greater control over their supply chains. By acquiring or partnering with companies involved in the production of mining equipment or the processing of raw materials, miners can reduce their dependency on external suppliers and achieve cost savings through economies of scale. This approach can also lead to improved quality control and more predictable supply chain dynamics, further stabilizing operational costs.

Finally, prudent financial management remains a cornerstone of cost control for gold miners. Companies must maintain a disciplined approach to capital expenditure, ensuring that investments are aligned with long-term strategic goals. Additionally, hedging strategies can be employed to protect against fluctuations in gold prices and currency exchange rates, providing a safeguard against potential financial losses.

In conclusion, while the current bullion boom presents a lucrative opportunity for gold miners, the accompanying rise in operational costs necessitates a strategic response. By embracing technological innovation, forming strategic partnerships, diversifying energy sources, pursuing vertical integration, and exercising prudent financial management, gold miners can effectively navigate the challenges posed by escalating expenses. Through these strategies, they can not only preserve their profit margins but also position themselves for sustainable growth in an increasingly competitive market.

Technological Innovations to Reduce Mining Costs

As the global demand for gold continues to rise, driven by economic uncertainties and the metal’s status as a safe-haven asset, gold miners are facing a paradoxical challenge. Despite the bullish market for bullion, mining companies are grappling with escalating operational costs that threaten to erode profit margins. In response, the industry is increasingly turning to technological innovations as a means to mitigate these expenses and enhance efficiency. This strategic pivot towards technology is not only essential for maintaining competitiveness but also for ensuring sustainable operations in the long term.

One of the primary areas where technology is making a significant impact is in the automation of mining processes. Automation technologies, including autonomous vehicles and drones, are being deployed to perform tasks that were traditionally labor-intensive. These technologies not only reduce the need for a large workforce but also enhance safety by minimizing human exposure to hazardous conditions. For instance, autonomous haul trucks and drilling systems can operate continuously without the need for breaks, thereby increasing productivity and reducing downtime. Moreover, drones equipped with advanced imaging technologies are being used for aerial surveys and monitoring, providing real-time data that can be used to optimize mining operations.

In addition to automation, the integration of data analytics and artificial intelligence (AI) is revolutionizing the way mining companies manage their operations. By harnessing the power of big data, miners can gain insights into various aspects of their operations, from equipment performance to ore quality. Predictive maintenance, powered by AI algorithms, allows companies to anticipate equipment failures before they occur, thereby reducing maintenance costs and preventing costly downtime. Furthermore, data analytics can be used to optimize the extraction process, ensuring that resources are utilized efficiently and waste is minimized.

Another technological advancement that is proving beneficial is the use of renewable energy sources to power mining operations. The transition to solar, wind, and other renewable energy sources is not only environmentally responsible but also economically advantageous. By reducing reliance on fossil fuels, mining companies can significantly lower their energy costs, which constitute a substantial portion of operational expenses. Additionally, the adoption of energy-efficient technologies, such as electric vehicles and energy management systems, further contributes to cost savings and reduces the carbon footprint of mining activities.

Moreover, advancements in mineral processing technologies are enabling miners to extract gold more efficiently and with less environmental impact. Innovative techniques, such as bioleaching and hydrometallurgical processes, offer alternatives to traditional methods that are often energy-intensive and environmentally damaging. These new methods allow for the extraction of gold from low-grade ores, which were previously considered uneconomical, thereby expanding the potential resource base and improving overall profitability.

In conclusion, as gold miners navigate the challenges posed by rising operational costs amid a booming bullion market, the adoption of technological innovations emerges as a crucial strategy. By embracing automation, data analytics, renewable energy, and advanced processing techniques, mining companies can not only reduce costs but also enhance their operational efficiency and sustainability. As the industry continues to evolve, these technological advancements will play an increasingly vital role in shaping the future of gold mining, ensuring that it remains a viable and profitable endeavor in the face of ever-changing market dynamics.

Labor Challenges Facing Gold Miners in a Bullion Boom

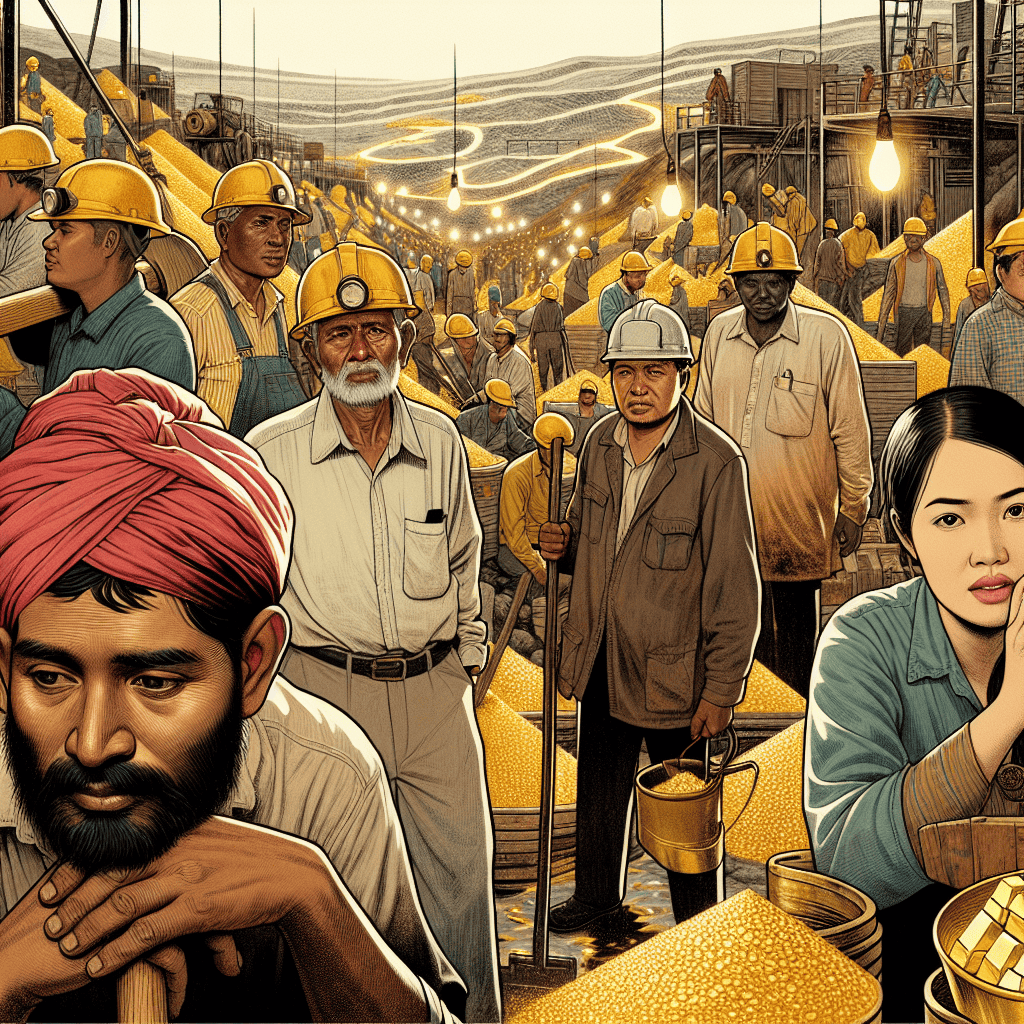

As the global economy navigates through uncertain times, the allure of gold as a safe-haven asset has intensified, leading to a significant boom in bullion prices. This surge has been a boon for investors and has sparked renewed interest in gold mining operations worldwide. However, despite the promising market conditions, gold miners are grappling with a myriad of challenges, particularly concerning labor costs and workforce management. These issues are becoming increasingly pronounced, threatening to undermine the potential benefits of the current bullion boom.

To begin with, the rising cost of labor is a primary concern for gold mining companies. As the demand for gold increases, so does the need for skilled labor to extract it. However, the mining industry is facing a shortage of qualified workers, a problem exacerbated by the aging workforce and the lack of new entrants into the field. This scarcity of skilled labor has led to increased competition among mining companies, driving up wages and benefits as firms strive to attract and retain talent. Consequently, labor costs have surged, eating into the profit margins that should have been bolstered by high gold prices.

Moreover, the geographical locations of many gold mines add another layer of complexity to labor challenges. Many of these mines are situated in remote areas, often requiring workers to relocate or endure long commutes. This geographical isolation can deter potential employees, further intensifying the labor shortage. Additionally, the harsh working conditions typical of mining operations, including long hours and physically demanding tasks, contribute to high turnover rates. Companies are thus compelled to invest more in training and recruitment, further inflating operational costs.

In addition to these logistical challenges, gold miners are also contending with increasing regulatory pressures related to labor practices. Governments worldwide are tightening regulations to ensure fair labor practices and improve working conditions in the mining sector. While these regulations are essential for safeguarding workers’ rights, they also impose additional financial burdens on mining companies. Compliance with these regulations often necessitates significant investments in safety equipment, training programs, and infrastructure improvements, all of which contribute to rising operational costs.

Furthermore, the global push towards sustainability and ethical sourcing has placed additional pressure on gold miners to adopt more responsible labor practices. Consumers and investors are increasingly demanding transparency and accountability in the supply chain, compelling mining companies to adhere to higher ethical standards. This shift necessitates further investment in labor management systems and practices, adding another layer of cost to mining operations.

Despite these challenges, some gold mining companies are exploring innovative solutions to mitigate labor-related costs. Automation and technological advancements are being leveraged to reduce reliance on manual labor, thereby decreasing labor costs and improving efficiency. However, the implementation of such technologies requires substantial upfront investment and may not be feasible for all operations, particularly smaller mining companies with limited resources.

In conclusion, while the current bullion boom presents lucrative opportunities for gold miners, the accompanying labor challenges pose significant hurdles. Rising labor costs, regulatory pressures, and the demand for ethical practices are all factors that mining companies must navigate carefully. As the industry continues to evolve, finding a balance between capitalizing on high gold prices and managing labor-related expenses will be crucial for sustaining profitability in the long term.

Environmental Regulations and Their Cost Implications for Gold Miners

As the global demand for gold continues to rise, driven by economic uncertainties and a burgeoning interest in safe-haven assets, gold miners find themselves in a paradoxical situation. While the price of bullion has reached impressive heights, the cost of extracting this precious metal has simultaneously escalated, largely due to stringent environmental regulations. These regulations, designed to mitigate the environmental impact of mining activities, have introduced a complex layer of compliance that significantly affects the operational costs of gold mining companies.

To begin with, the implementation of environmental regulations has necessitated substantial investments in technology and infrastructure. Gold mining operations are now required to adopt more sustainable practices, which often involve the use of advanced machinery and processes that minimize ecological disruption. For instance, the introduction of cleaner technologies to reduce emissions and manage waste effectively has become a mandatory aspect of mining operations. While these technologies are essential for reducing the environmental footprint, they come with a hefty price tag, thereby increasing the overall cost of production.

Moreover, the regulatory landscape is continuously evolving, with governments around the world tightening their environmental policies. This evolution is partly driven by increased public awareness and advocacy for environmental conservation, which has put pressure on policymakers to enforce stricter standards. Consequently, gold miners are compelled to allocate more resources towards compliance, including hiring environmental experts and conducting regular audits to ensure adherence to regulations. These additional expenditures, while crucial for maintaining operational licenses, further strain the financial resources of mining companies.

In addition to technological investments and compliance costs, gold miners also face challenges related to land rehabilitation and restoration. Environmental regulations often mandate that mining companies restore mined land to its original state or to a condition that supports alternative uses. This requirement involves extensive planning and execution, including soil treatment, reforestation, and water management, all of which are resource-intensive processes. The financial burden of these activities is substantial, and for many mining companies, it represents a significant portion of their operational budget.

Furthermore, the complexity of navigating environmental regulations can lead to delays in project timelines, which in turn affects profitability. Obtaining the necessary permits and approvals is a time-consuming process, often fraught with bureaucratic hurdles. Delays in securing these permits can stall mining operations, leading to increased costs and lost revenue opportunities. For gold miners, time is of the essence, and any disruption in the production schedule can have far-reaching financial implications.

Despite these challenges, it is important to recognize that environmental regulations play a crucial role in promoting sustainable mining practices. They ensure that the extraction of gold does not come at the expense of ecological degradation and that mining companies are held accountable for their environmental impact. In the long run, adherence to these regulations can enhance the reputation of mining companies, making them more attractive to investors who are increasingly prioritizing sustainability in their investment decisions.

In conclusion, while the current bullion boom presents lucrative opportunities for gold miners, the associated costs of complying with environmental regulations cannot be overlooked. These regulations, though financially demanding, are essential for fostering a sustainable mining industry. As gold miners navigate this challenging landscape, they must balance the pursuit of profitability with their responsibility towards environmental stewardship, ensuring that their operations contribute positively to both the economy and the environment.

The Role of Supply Chain Disruptions in Increasing Mining Costs

In recent years, the gold mining industry has experienced a paradoxical situation where, despite a significant boom in bullion prices, miners are grappling with escalating costs that threaten to erode their profit margins. This conundrum is largely attributed to supply chain disruptions, which have become a formidable challenge for the industry. As gold prices soar, driven by economic uncertainties and increased demand for safe-haven assets, miners are finding it increasingly difficult to capitalize on these favorable market conditions due to the rising costs associated with extracting and processing the precious metal.

One of the primary factors contributing to these increased costs is the disruption in global supply chains, a phenomenon exacerbated by the COVID-19 pandemic. The pandemic has led to widespread logistical challenges, including delays in the transportation of essential mining equipment and materials. Consequently, mining companies are facing prolonged lead times and increased shipping costs, which have a direct impact on their operational expenses. Furthermore, the scarcity of critical components, such as machinery parts and explosives, has forced companies to seek alternative suppliers, often at a premium, thereby inflating their cost structures.

In addition to logistical hurdles, labor shortages have also played a significant role in driving up mining costs. The pandemic has resulted in workforce disruptions, with many skilled workers unable or unwilling to return to remote mining sites due to health concerns or travel restrictions. This has led to increased labor costs as companies offer higher wages and incentives to attract and retain the necessary talent. Moreover, the need to implement stringent health and safety protocols to protect workers from the virus has added another layer of expenses, further straining the financial resources of mining operations.

Another critical aspect of supply chain disruptions affecting mining costs is the volatility in energy prices. Mining is an energy-intensive industry, and fluctuations in fuel and electricity prices can have a substantial impact on operational costs. The pandemic-induced disruptions in global energy markets have led to unpredictable price swings, making it challenging for mining companies to manage their energy expenditures effectively. As a result, many miners are exploring alternative energy sources and investing in renewable energy projects to mitigate these risks, although such initiatives often require significant upfront capital investment.

Moreover, geopolitical tensions and trade disputes have compounded the supply chain challenges faced by gold miners. Tariffs and trade barriers have increased the cost of importing essential goods and services, while political instability in key mining regions has disrupted production schedules and increased the risk of supply chain interruptions. These factors have forced mining companies to adopt more resilient and flexible supply chain strategies, such as diversifying their supplier base and investing in local sourcing, to safeguard against future disruptions.

In conclusion, while the current bullion boom presents a lucrative opportunity for gold miners, the industry is simultaneously contending with a complex web of supply chain disruptions that are driving up costs and squeezing profit margins. To navigate these challenges, mining companies must adopt innovative strategies to enhance supply chain resilience, optimize operational efficiency, and manage costs effectively. By doing so, they can better position themselves to capitalize on the favorable market conditions and ensure sustainable growth in the face of ongoing uncertainties.

Q&A

1. **Question:** What are the primary factors contributing to the rising costs for gold miners?

– **Answer:** Rising energy prices, increased labor costs, and supply chain disruptions are primary factors contributing to the rising costs for gold miners.

2. **Question:** How has the price of gold bullion changed recently?

– **Answer:** The price of gold bullion has increased, reaching near-record highs due to economic uncertainty and increased demand for safe-haven assets.

3. **Question:** What impact do higher operational costs have on gold mining companies’ profitability?

– **Answer:** Higher operational costs reduce profit margins for gold mining companies, even as gold prices rise, making it challenging to capitalize on the bullion boom.

4. **Question:** How are gold miners attempting to manage or mitigate these rising costs?

– **Answer:** Gold miners are investing in more efficient technologies, renegotiating supplier contracts, and exploring cost-cutting measures to manage rising costs.

5. **Question:** What role does geopolitical instability play in the gold mining industry?

– **Answer:** Geopolitical instability can lead to increased demand for gold as a safe-haven asset, but it can also disrupt mining operations and supply chains, further increasing costs.

6. **Question:** Are there any environmental or regulatory challenges affecting gold miners?

– **Answer:** Yes, stricter environmental regulations and the need for sustainable mining practices are increasing compliance costs for gold miners.

7. **Question:** How are investors reacting to the struggles faced by gold miners despite the bullion boom?

– **Answer:** Investors are cautious, weighing the high gold prices against the increased operational costs and potential risks, leading to mixed investment strategies in the sector.

Conclusion

Gold miners are facing significant challenges despite a boom in bullion prices, primarily due to escalating operational costs. These costs, driven by factors such as increased labor expenses, energy prices, and regulatory compliance, are eroding profit margins and limiting the financial benefits that would typically accompany rising gold prices. Additionally, supply chain disruptions and geopolitical tensions are exacerbating these cost pressures. As a result, gold mining companies are compelled to focus on efficiency improvements, cost management strategies, and technological innovations to sustain profitability. The struggle underscores the complex dynamics of the mining industry, where high commodity prices do not automatically translate into increased profitability.